Silicon Microarray™

Spotting Pins : PETC Pins

Please

contact us for further information about how to purchase or license these

technologies. OEM inquiries welcome.

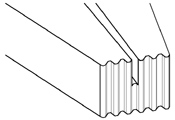

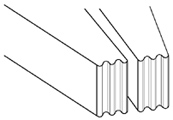

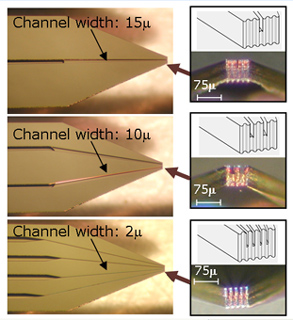

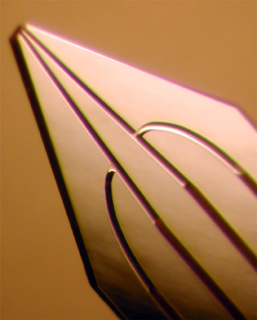

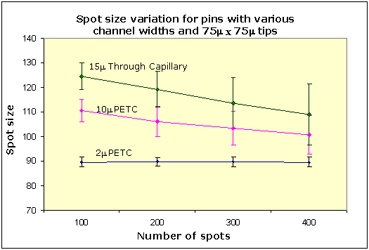

Parallel is very pleased to announce the introduction of silicon pins with Partially Etched Through Channel (PETC), the next generation Silicon Microarray™ micromachined silicon printing tools, to increase the ease and accuracy of printing your DNA, protein or other microarrays. Unlike the classic Si pins, whose internal channels are open to the outer surfaces on both sides of the pin shaft, PETCs contain channels that are open to only one of the two outer surfaces (Fig 1, 2 and 3). These new ultra-precise set of silicon printing tools can deliver up to four times as many spots as our classic pins with a %CV for spot-to-spot uniformity of only 2%. The greatly improved performance derives from the ultraprecise silicon micromachining techniques which can be used to sculpt miniscule pin tip features. The print fluid conduit connecting the reservoir and print tip does not pass all the way through the pin shaft but passes only part way through the shaft. This design functionally mimics a miniscule flow restrictor precisely metering the print fluid through the restriction to the substrate resulting in a more uniform delivered flow.

Features,

Advantages and Benefits of PETC Pins Table1 Features, advantages and Benefits of the PETC pin designs

Printing

Performance of PETC Pins

It is interesting to note that there is a strong effect from the size of the channel connecting the reservoir on the deposited spot size. A commonly held misconception is that somehow during microcontact printing, the printing fluid deposited onto the substrate from the pin's print tip which is parallel to the substrate. A cursory analysis shows that there is not nearly enough fluid on the print tip surface to account for the deposited drop volume. For example, even if the film of printing fluid adhering to the surface of the print tip that is parallel to the substrate is 1Ám thick and the print tip is 75Ám x 75Ám , there are only about 5 pL of printing fluid on the print tip. However, based on the number of spots obtained per dip of the pin, the deposited spot volume of a printing fluid like random cy3-labeled 9-mers in 3X SSC on amine coated glass slides is closer to 200-300 pL. Therefore, the printing fluid on the pin's print tip is only a few percent of the total deposited drop volume. Since there is not nearly enough fluid adhering to the print tip to account for the observed spot volume, the deposited volume must originate from within the fluid filled channel connecting the print tip. Furthermore, most of the deposited spot volume is removed from the channel as the pin is drawn away from the substrate. In other words, the wettable substrate surface draws the fluid from the pin shaft as the pin is withdrawn away from the surface. Further support for this mechanism is provided by study the printing behavior of a pin in which there is a thin (<10Ám ) film of silicon directly on the print tip and parallel to the surface of the substrate (i.e. connecting the tips of the two prongs of the split pin shaft together). Even though photomicrographs show the entire print tip to be covered with a thin film of water, this type of pin will not print multiple spots - presumably due to the inability of the substrate to remove the printing fluid from the channel because of the silicon separator between the channel and substrate.The improved design manifests itself in more spots printed per source plate visit and a substantially higher pin to pin uniformity. Table 2 compares the printing parameters and spot size uniformity for two different PETC pin tips to a classic pin tip with the same tip size and uptake volume. Table

2 Comparison

of arrays printed with Si Pins having 75Ám x 75Ám tip size

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

3054 Lawrence Expy. Santa Clara, CA 95051

info@parallel-synthesis.com, Phone:(408) 749-8318 Fax:(408) 749-8318